Battery Management and Charger System

PowerGuard BMS is a battery management and charging system used to monitor, optimize, and control the charging of batteries in armored vehicles. This system controls the battery voltage, current, and temperature to prevent batteries from overcharging, overheating, or failing. It is also used to test the battery for performance loss.

BMS System provides all information, errors, and emergency situations of the batteries to the user while Tedeg has developed a complete system by adding a battery charger unit to the system with its own developed innovation.

PowerGuard BMS Battery management with its newly developed battery equalization feature has the ability to equalize the main vehicle batteries and weapon tower batteries in the system. This feature automatically outputs when the vehicle batteries are full, connects the weapon batteries to the system, and includes the charging process in the vehicle batteries.

PowerGuard BMS battery management and charging system is of critical importance in armored vehicles. This system helps to extend the performance and life of the vehicles by ensuring that the batteries work safely and efficiently. In addition, the system also reduces safety risks such as fires and explosions by preventing battery failures.

Information Form

- Description

- Additional information

Description

The important benefits of the PowerGuard BMS system are:

- Extends battery life

- Increases battery performance

- Prevents battery failures

- Reduces safety risks

- Optimizes the charging process

- Provides information about the battery to the user

- PowerGuard BMS system is an ideal solution for battery management in armored vehicles. This system helps to extend the performance and life of the vehicles by ensuring that the batteries work safely and efficiently

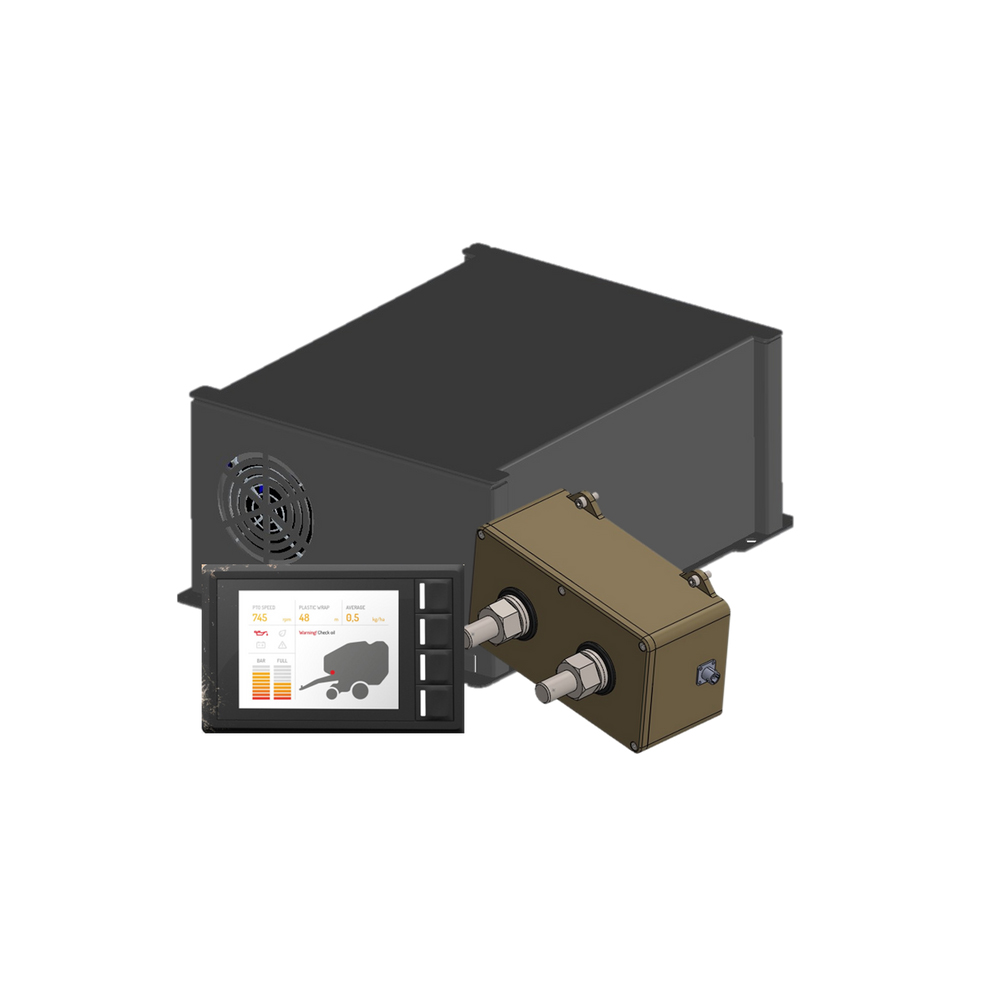

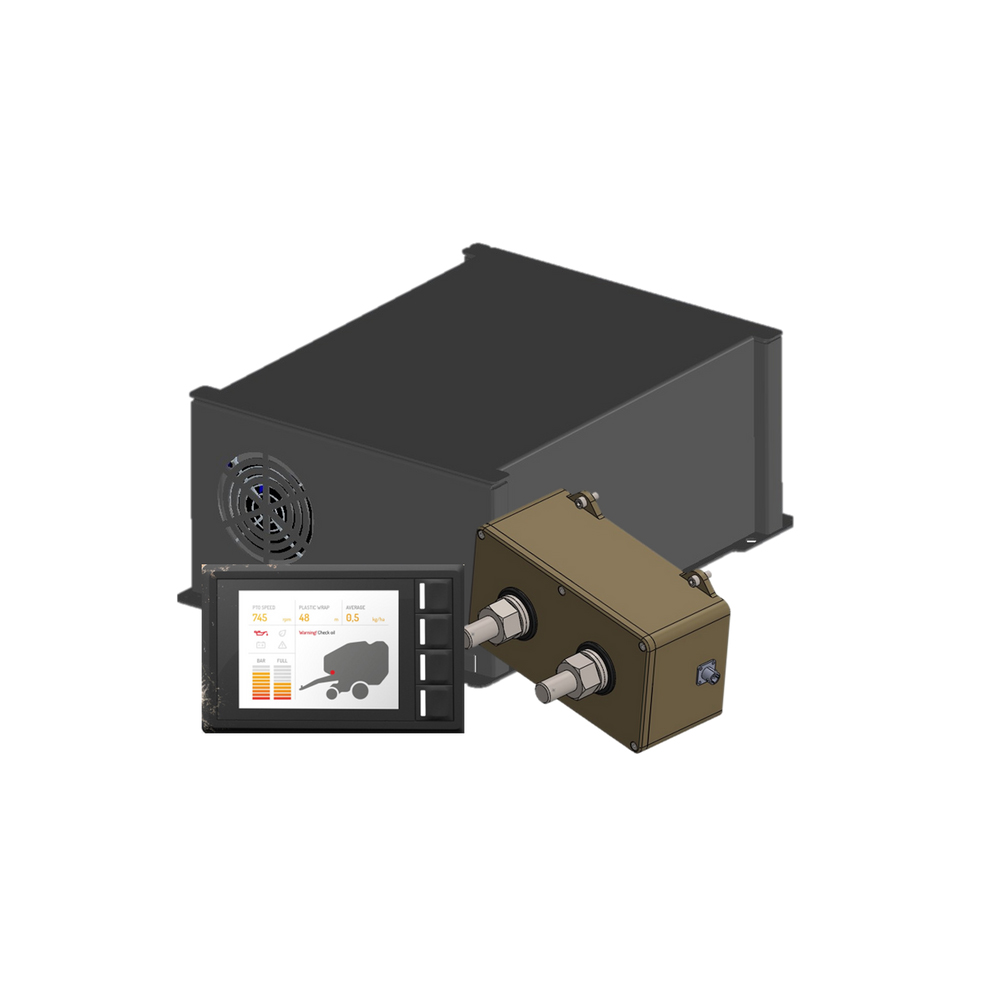

- Tedeg Defense provides its PowerGuard BMS system to its customers as a turnkey system. The system consists of the following components:

PowerGuard BMS System Components:

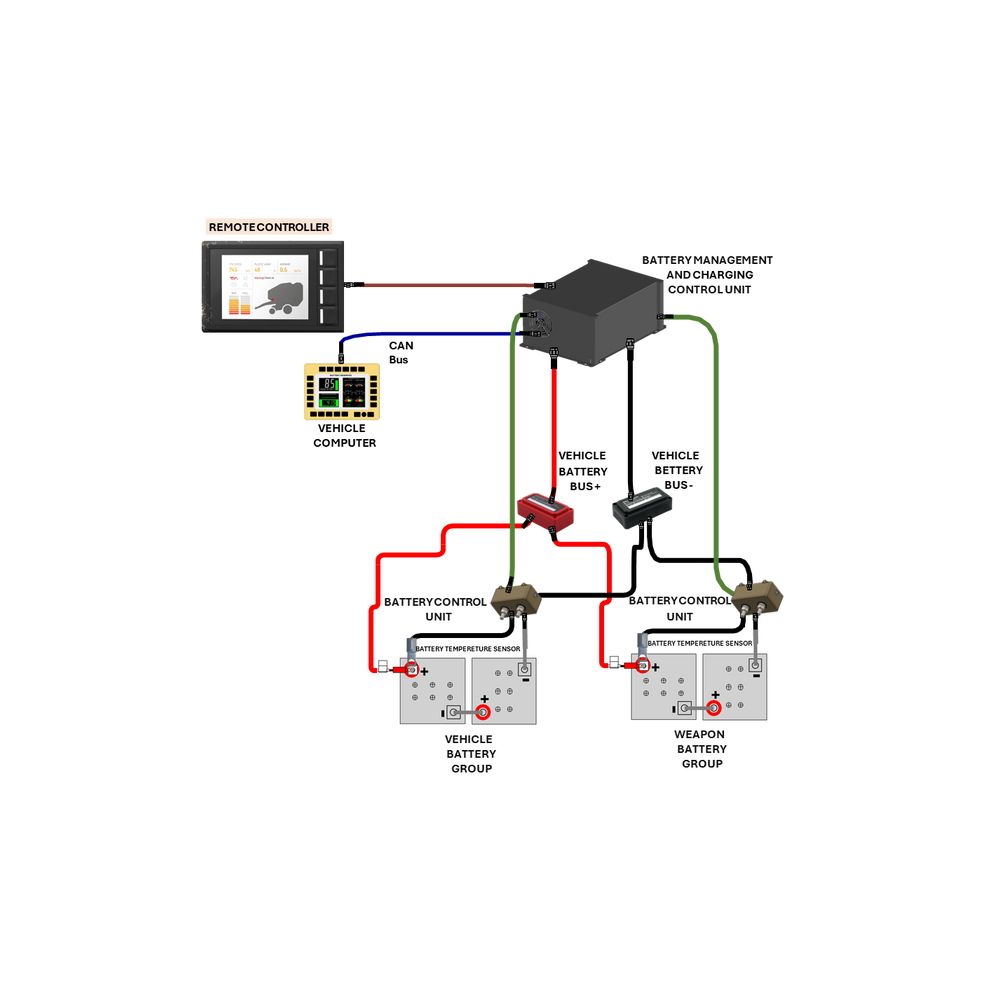

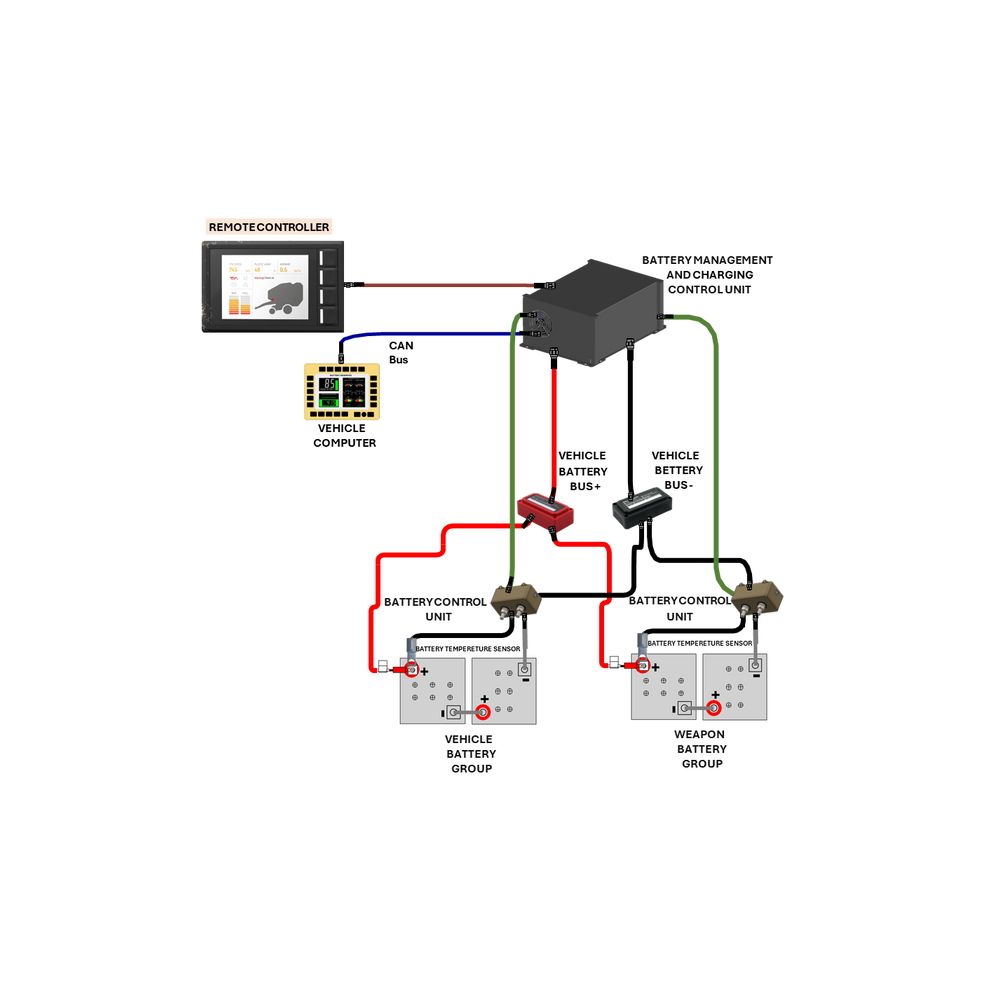

- Control Unit (Battery Charger Unit): The brain of the PowerGuard BMS system, the control unit monitors the batteries and controls the charging process. It also communicates with the remote control unit and the battery control and measurement boxes.

- Remote Control Unit: Allowing the user to monitor and control the system from a distance, the remote control unit can be used to view battery status, start and stop charging, and set alarm thresholds.

- Battery Control and Measurement Box (Shunt): Installed near each battery, the battery control and measurement boxes monitor the battery’s voltage, current, and temperature and send this data to the control unit.

- Battery Temperature Sensor: Attached to the batteries, the battery temperature sensors measure their temperature. This data is sent to the control unit to help prevent overcharging and overheating.

- Military Electrical Installation: The wiring and cabling that connects the components of the system together is the military electrical installation.

The PowerGuard BMS system is controlled by a single control unit. This control unit controls both the Battery Management System and the Battery Charger Unit. This control unit is called the Battery Management and Charger Control Unit and is located in the vehicle.

Battery information and errors from the Battery Management System are collected and controlled in the Battery Management and Charger Control Unit.

All information collected in the Battery Management and Charger Control Unit is sent from here to the remote control, and all commands from the remote control are distributed to the system from the Battery Management and Charger Control Unit.

Here is a more detailed description of the system operation scenario:

- Battery Monitoring: The Battery Management System monitors the voltage, current, and temperature of each battery in the system. This data is sent to the Battery Management and Charger Control Unit.

- Battery Control: The Battery Management and Charger Control Unit uses the battery data to control the charging process. It ensures that the batteries are charged safely and efficiently, and it prevents them from overcharging, overheating, or failing.

- Remote Control: The user can monitor and control the system using the remote control unit. They can view battery status, start and stop charging, and set alarm thresholds.

- System Diagnostics: The Battery Management System diagnoses battery problems and alerts the user to potential issues.

Additional information

| Maximum Current | 200 Amps |

|---|---|

| Starter Motor Input | Yes |

| Battery Voltage | 12-24 VDC |

| Weight | 26 lbs (With Battery Charger) |

| AC Input Voltage | 90-264 VAC |

| AC Input Frequency | 50/60Hz |

| AC Input Current | 7-28 AMPS@230 V AC |

| Output (Supply) Voltage | 28 VDC |

| Output Current | 20-200 AMPS MAX.@ 28V DC |

| Military Standard Compliance | MIL-STD-810G, MIL-STD-461F |

| Temperature Dependent Automatic Supply | Yes |

| Short Circuit Protection | Yes |

| Data Collection with Communication Connections | Yes |

| Reading Output Current | Yes |

| Displaying Supply Voltage and Output Current on Screen | Yes |

| Direct Communication with Battery Management System | Yes |

| Temperature Dependent Supply Current Change | 100% up to 70 °C |

TECHNICAL DOCUMENT - EN

Additional information

| Maximum Current | 200 Amps |

|---|---|

| Starter Motor Input | Yes |

| Battery Voltage | 12-24 VDC |

| Weight | 26 lbs (With Battery Charger) |

| AC Input Voltage | 90-264 VAC |

| AC Input Frequency | 50/60Hz |

| AC Input Current | 7-28 AMPS@230 V AC |

| Output (Supply) Voltage | 28 VDC |

| Output Current | 20-200 AMPS MAX.@ 28V DC |

| Military Standard Compliance | MIL-STD-810G, MIL-STD-461F |

| Temperature Dependent Automatic Supply | Yes |

| Short Circuit Protection | Yes |

| Data Collection with Communication Connections | Yes |

| Reading Output Current | Yes |

| Displaying Supply Voltage and Output Current on Screen | Yes |

| Direct Communication with Battery Management System | Yes |

| Temperature Dependent Supply Current Change | 100% up to 70 °C |