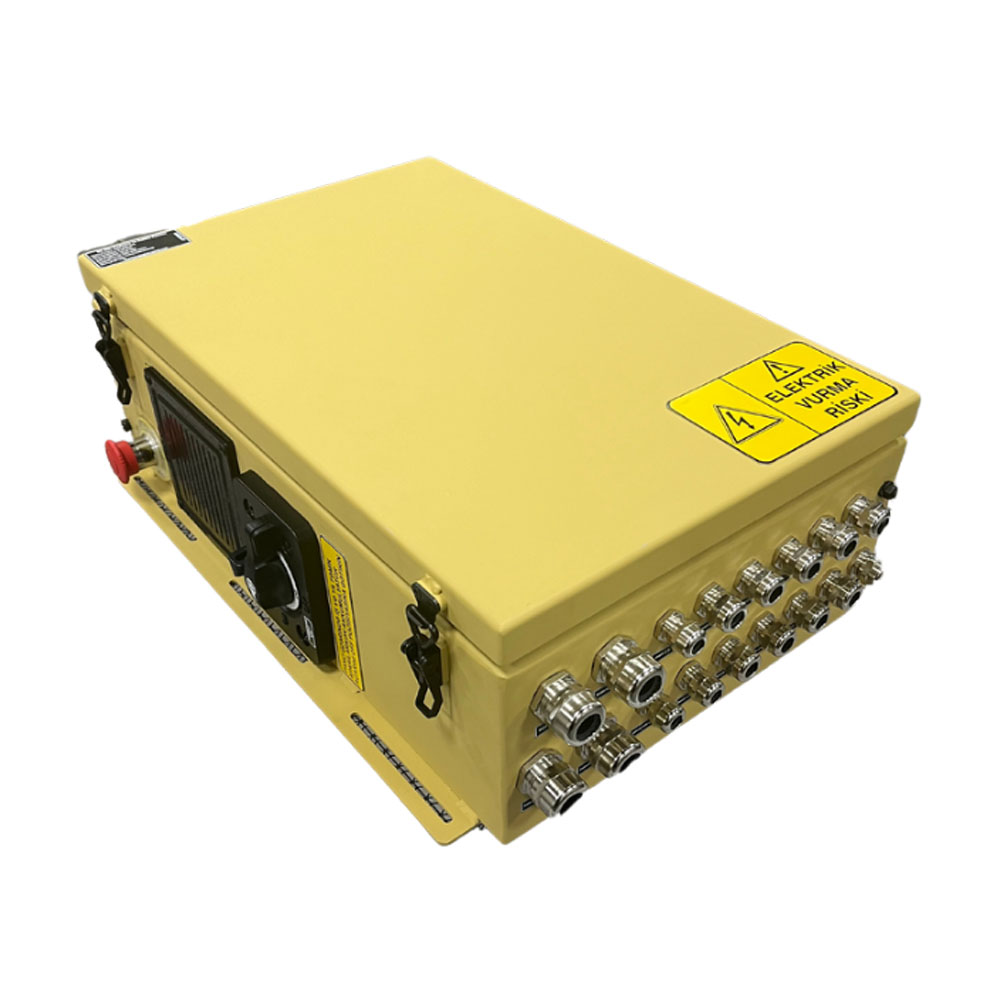

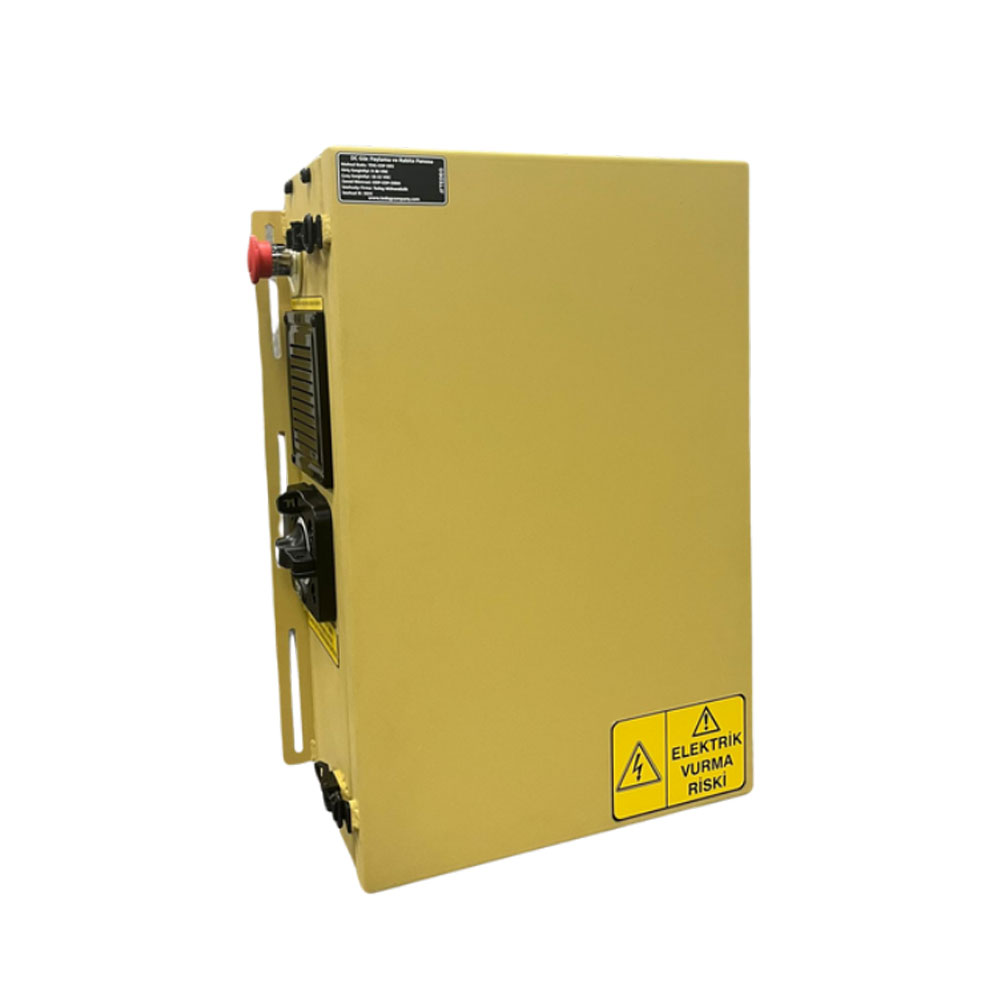

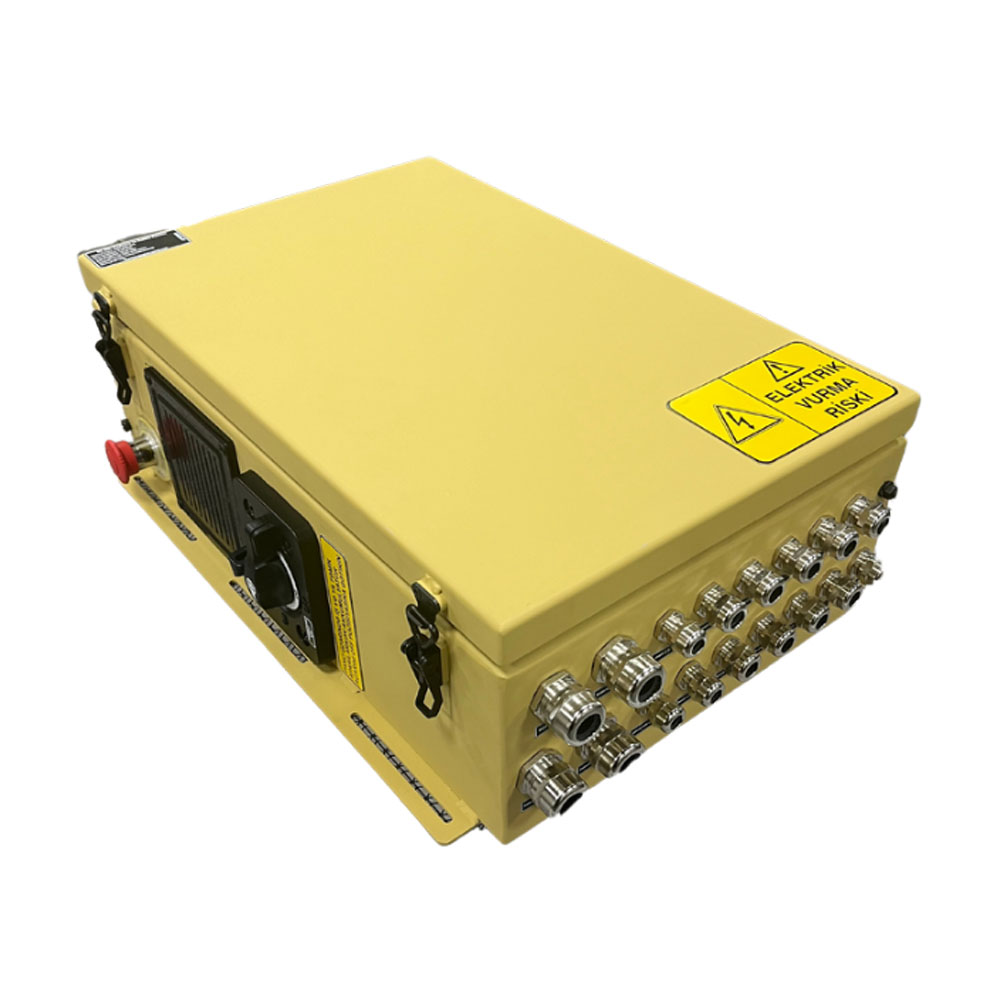

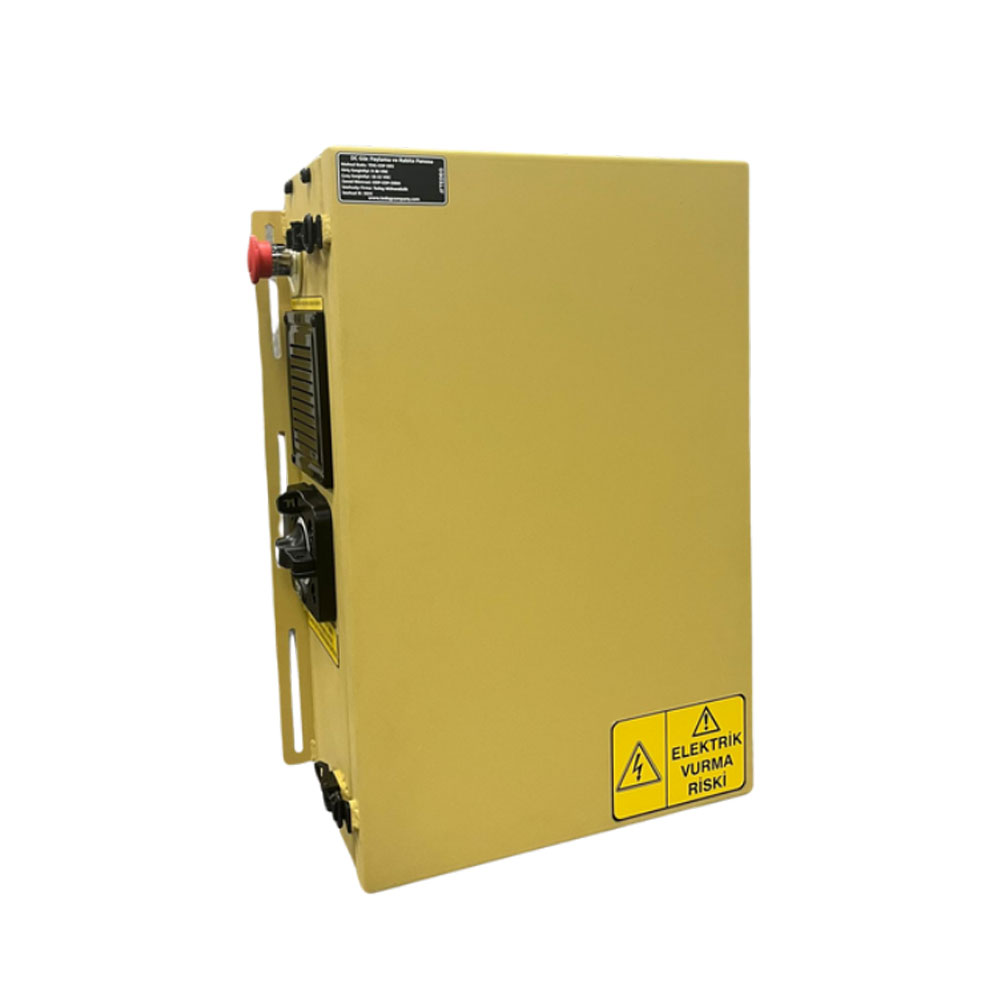

DC Power Distribution Unit

Developed by Tedeg Defence, the DC Power Distribution Unit is a power management device that collects energy from various DC power sources and distributes it to systems. Manufactured to military standards, this product offers high reliability and efficiency. This product by Tedeg Defence is designed to meet the MIL-STD-810G rain standard and has successfully passed all tests. It intelligently collects DC power from different sources with varying capacities and voltages, converting them into the DC and AC power needed by the complex main system, managing and supplying the system.

Information Form

- Description

- Additional information

Description

Purpose

The purpose of this product is to collect energy from various DC power sources and distribute it reliably and efficiently to systems. This is especially important for providing uninterrupted power in military vehicles and critical infrastructure systems.

Applications

- Military Vehicles: For stabilizing power systems and operating various devices.

- Industrial Facilities: To provide the specific DC voltages needed for production machinery.

- Emergency Systems: To meet the energy needs of systems requiring uninterrupted power.

Features

- High Efficiency: Minimizes energy losses.

- Wide Input Voltage Range: Can be powered from various energy sources.

- Robust Construction: Ensures reliable performance under harsh conditions.

- Protection Features: Includes advanced safety features such as overload, short circuit, and temperature protection.

- Modular Design: Facilitates easy maintenance and repair.

- Digital Communication and Fault Reporting: The product can send all faults, warnings, and status information to the user and main control unit via Ethernet and RS-482 communication infrastructure. It has OLED screens for digitally displaying faults and information. The unit allows error, warning, on/off, and operating threshold values to be changed and programmed through the Ethernet interface and desktop web control software.

- Multiple Inputs and Outputs: Equipped with 4 inputs (Battery 1, Battery 2, Alternator, Battery Charger) and various output capacities with MIDI type fuses. Each output has its own fuse.

- Cooling System: Thermostat-controlled fans provide temperature management.

- EMI Protection: EMI protection ensures electromagnetic compatibility in the military field.

- 6 Different DC Busbars: Efficiently and intelligently manages power and reports to the user.

- Remote Control and Monitoring: Offers remote control and monitoring capabilities, allowing the system’s status and performance to be continuously monitored and managed.

Keywords and LSI Keywords

- Keywords: DC power distribution unit, power management system, high efficiency, industrial power solutions, military power systems, DC-DC converter.

- LSI Keywords: Voltage distribution unit, energy management, DC power supply, military standards, EMI/EMC protection, modular power solution.

How It Works

The DC Power Distribution Unit collects energy from various DC power sources and distributes it according to system requirements. The product filters and protects the energy inputs, then converts them to the appropriate voltage levels for output. The advanced control unit monitors and manages parameters such as temperature, voltage, and current.

Components

- Input Filters: Regulate the input voltage and prevent potential interference.

- AC-DC Converter: Converts input AC voltage to DC.

- DC-AC Converter: Converts DC voltage to the desired AC voltage and frequency.

- Control Unit: Manages the conversion processes and controls output parameters.

- Output Filters: Regulate the output voltage and provide a pure sine wave.

- OLED Screens: Display digital fault and information notifications.

- Cooling Fans: Thermostat-controlled fans provide temperature management.

- MIDI Type Fuses: Output fuses with various amperage capacities.

Compliance with Test Standards

- EMC Compliance: Meets electromagnetic compatibility tests.

- Safety Tests: Passed overload, short circuit, and temperature protection tests.

- Military Standards: Tested in accordance with military standards such as MIL-STD-810G.

Functionality

This product collects energy from various DC power sources and safely and efficiently distributes it to systems, ensuring uninterrupted power. It is particularly useful for standardizing energy requirements across different regions and in specialized applications.

Additional information

| Number of Entries | 4 |

|---|---|

| Input Types | Battery 1, |

| Busbar | (+) and (-) type 400 Ampere Busbar |

| Cable Connector Transitions | IP67 Type PG Gland suitable for cable diameter |

| Output Fuse Type and Capacity | MIDI Type, 100 Amps @28 VDC |

| Spare Fuse Types and Its capacity | 3 pieces, 30 Amp MIDI Type |

| Cooling Type | 2 Axial Fans (In the Suction Section) |

| Hinge | There is. Torque Type Hinge |

| Thermostat | It comes into play at 30 °C and above and starts the cooling fans gradually. |

| Sealing | MIL-STD810G, Method 506.5, |

| EMI/EMC Protection | There is. EMI gasket. |

| Operating temperature | -32 , +52 °C |

| Battery Breaker | Yes |

| Weight | 14 ± 2 KG |

| Emergency Stop Button | Yes |

| Part number TDG-EDP-D0X | x= |

TECHNICAL DOCUMENT - EN

Additional information

| Number of Entries | 4 |

|---|---|

| Input Types | Battery 1, |

| Busbar | (+) and (-) type 400 Ampere Busbar |

| Cable Connector Transitions | IP67 Type PG Gland suitable for cable diameter |

| Output Fuse Type and Capacity | MIDI Type, 100 Amps @28 VDC |

| Spare Fuse Types and Its capacity | 3 pieces, 30 Amp MIDI Type |

| Cooling Type | 2 Axial Fans (In the Suction Section) |

| Hinge | There is. Torque Type Hinge |

| Thermostat | It comes into play at 30 °C and above and starts the cooling fans gradually. |

| Sealing | MIL-STD810G, Method 506.5, |

| EMI/EMC Protection | There is. EMI gasket. |

| Operating temperature | -32 , +52 °C |

| Battery Breaker | Yes |

| Weight | 14 ± 2 KG |

| Emergency Stop Button | Yes |

| Part number TDG-EDP-D0X | x= |