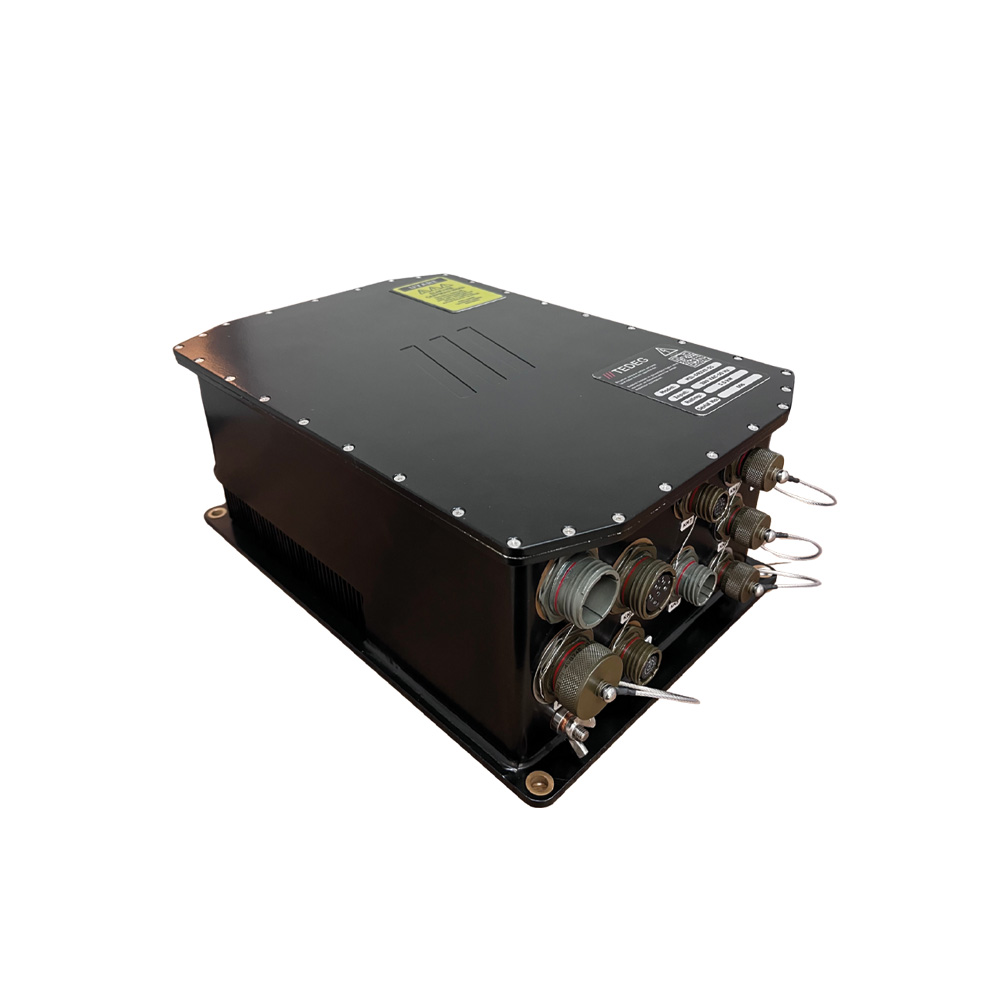

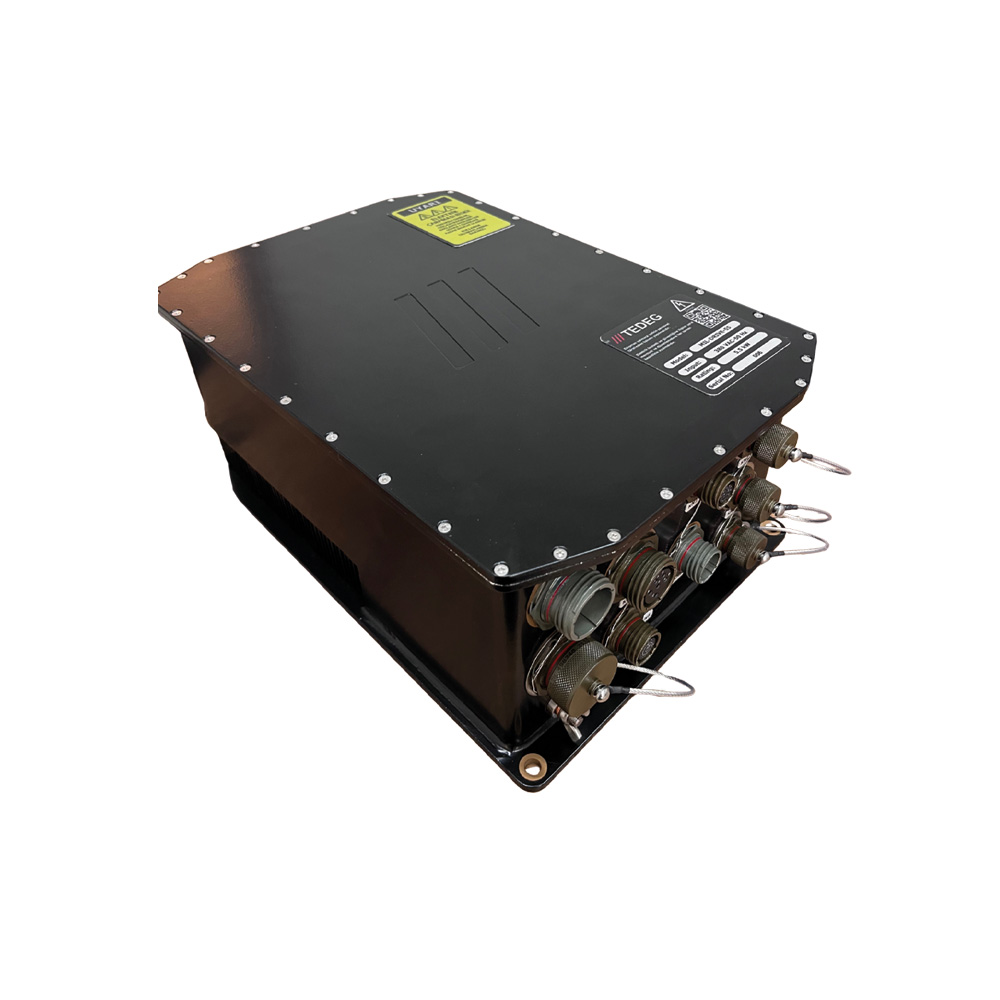

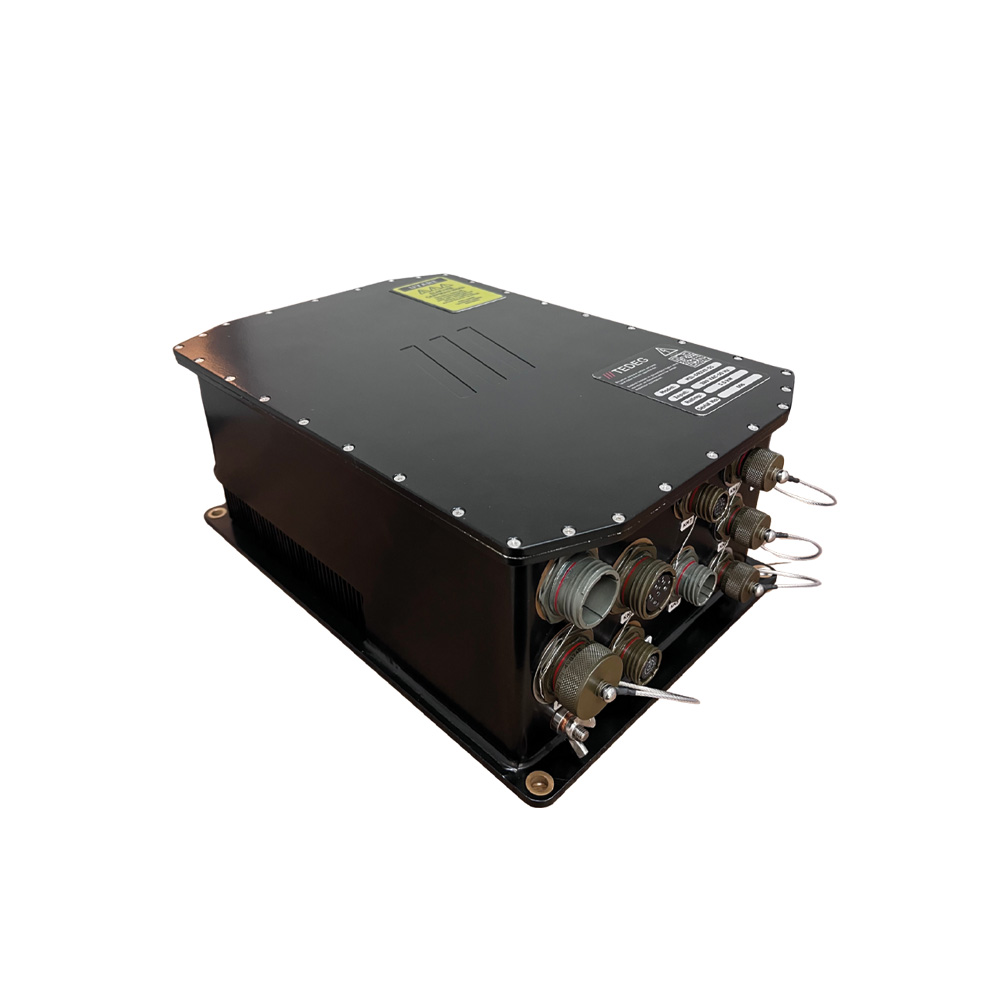

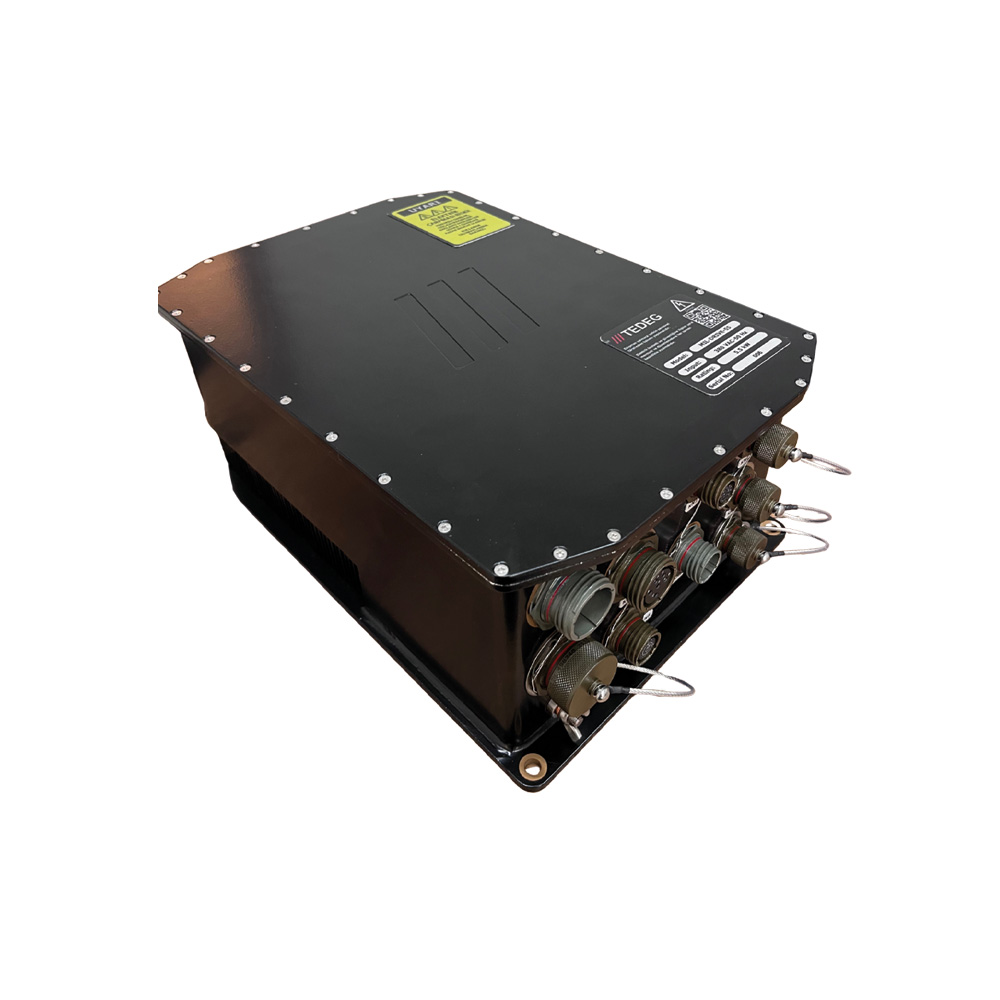

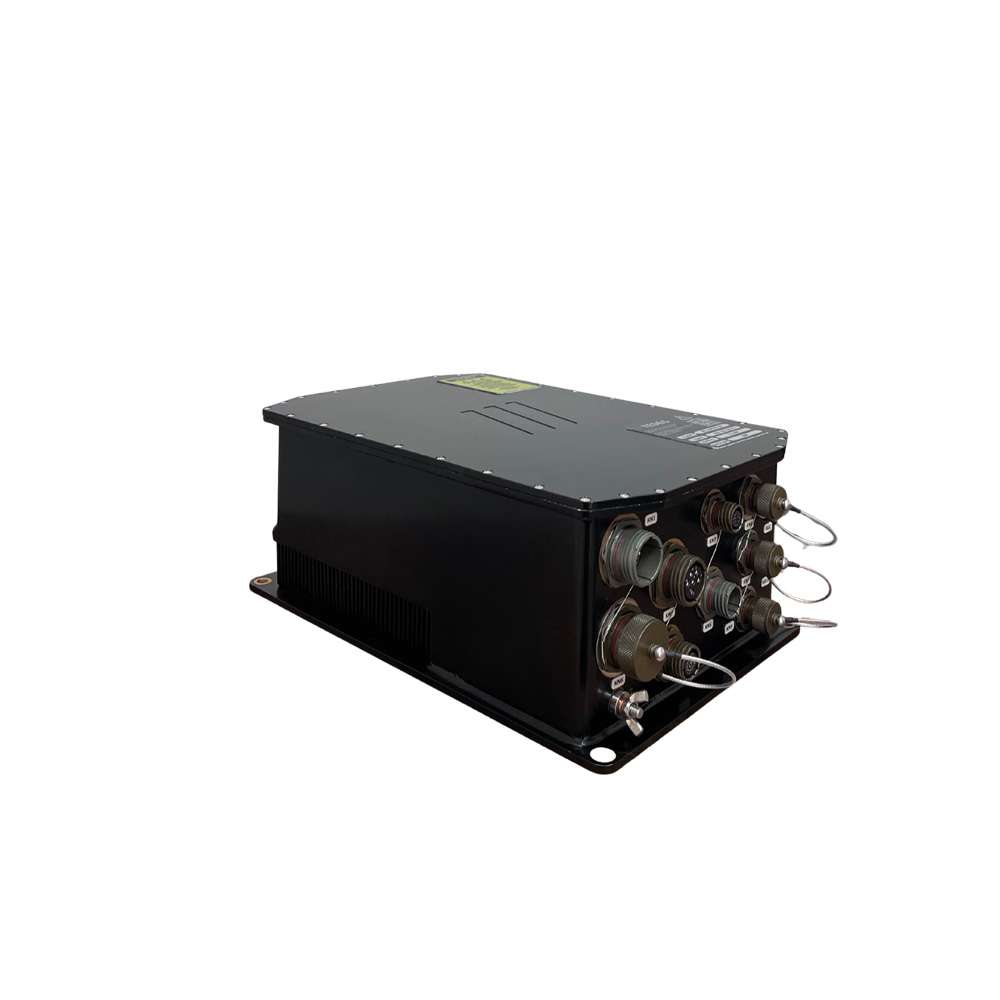

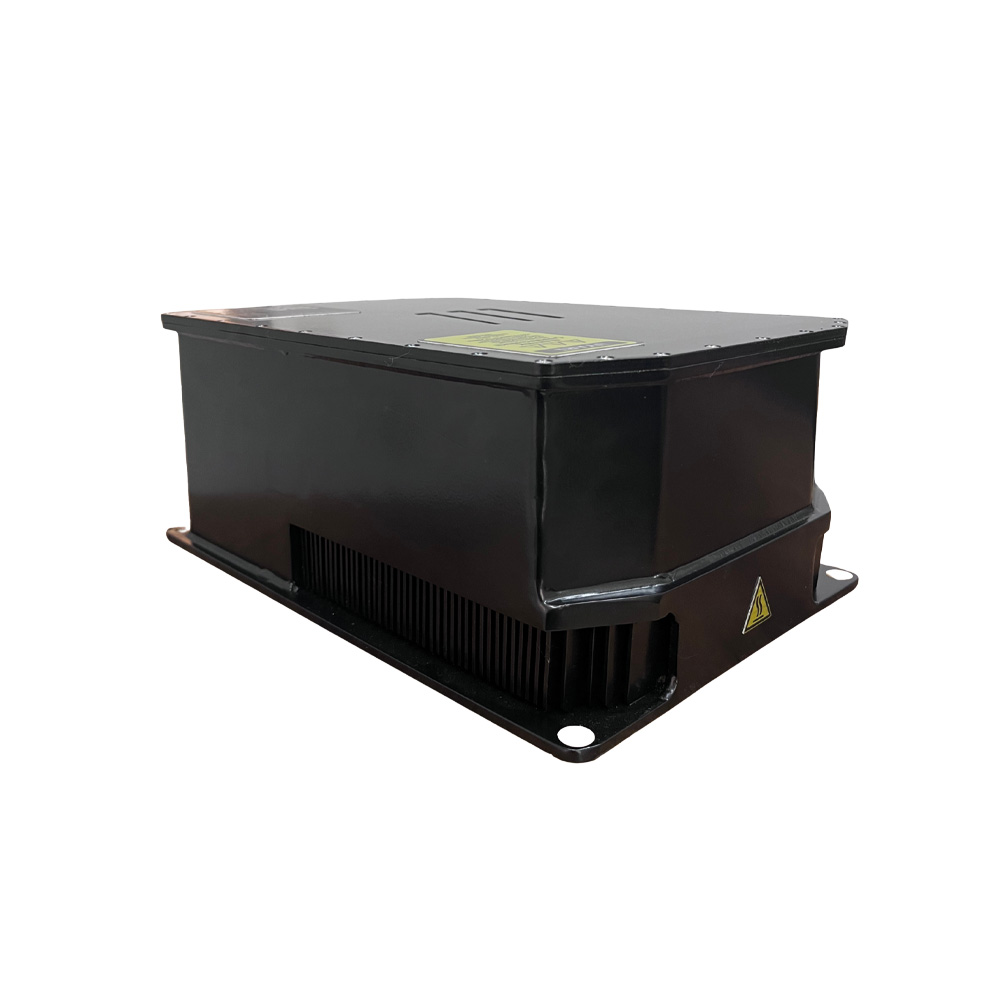

Mil-Drive-55 Military Motor Drive and Control Unit

The Mil-Drive-55 Military Motor Drive and Control Unit, developed by TEDEG Defense, is a MIL-STD-810G / MIL-STD-461F compliant, IP67-rated, and passively cooled intelligent motor control unit.

This system is an advanced military motor drive solution designed to precisely control the speed, torque, and direction of three-phase asynchronous motors.

The TEDEG motor control system architecture utilizes FOC (Field Oriented Control) algorithms to analyze the motor’s magnetic field in real time, ensuring high-efficiency and stable power management.

The Mil-Drive-55 FOC motor drive processes platform power and I/O signals — including resolver, incremental or absolute encoder, NTC, emergency inputs, Safe Torque Off (STO), RS-485, and CAN-Bus — through embedded control algorithms.

These data are evaluated within the system’s real-time control loops, allowing the motor’s behavior to be continuously optimized according to mission conditions.

As a result, the device delivers silent, stable, and high-precision motor operation.

Information Form

- Description

- Additional information

Description

With its fully compliant military-grade design and IP67 motor drive protection, the Mil-Drive-55 provides complete resistance to dust, humidity, rain, vibration, and electromagnetic interference.

Its fanless, passively cooled structure offers maintenance-free, long-lasting performance.

This rugged design makes the product ideal for demanding applications such as armored land vehicles, radar systems, electro-optic turrets, missile launch platforms, mobile mission units, and naval systems.

The integrated Safe Torque Off (STO) function enhances system safety by immediately cutting motor torque in emergency situations, ensuring mission reliability and personnel protection.

Additionally, secure data communication can be established with central control systems via RS-485 and CAN-Bus protocols.

The intelligent motor control unit architecture enables operators to perform remote monitoring, fault diagnostics, and telemetry management with ease.

Developed as part of the TEDEG motor control system, the Mil-Drive-55 not only drives the motor but also manages energy, controls motion, and ensures operational safety.

Thanks to its FOC motor drive technology, Safe Torque Off (STO) safety architecture, and MIL-STD-810G / MIL-STD-461F compliance, the Mil-Drive-55 Military Motor Drive stands out as the most advanced indigenous solution for defense applications requiring high precision, durability, and reliability.

Purpose

The primary purpose of the Mil-Drive-55 Military Motor Drive and Control Unit is to deliver precise speed, torque, and directional control of electric motors used in military platforms, while ensuring safe and stable power management.

Developed as part of the TEDEG motor control system, the product is designed as an intelligent motor control unit that operates with advanced embedded software algorithms capable of processing platform I/O signals and sensor feedback in real time.

This allows the Mil-Drive-55 to provide efficient, silent, and highly accurate motor control in field operations.

The Mil-Drive-55 Military Motor Drive utilizes Field Oriented Control (FOC) technology to analyze the magnetic field of the motor and deliver high-precision speed and torque regulation.

Its embedded control algorithms continuously evaluate sensor feedback from the platform, forming a dynamic internal control unit that adjusts motor behavior in real time according to mission requirements.

As a result, the Mil-Drive-55 FOC motor drive offers superior efficiency, low noise, and enhanced operational safety.

The integrated Safe Torque Off (STO) function immediately cuts motor torque during emergency events, protecting both the operator and the system.

This dual-channel STO architecture provides full support for safe shutdown and restart sequences, which is especially critical for mission-critical systems such as armored vehicles, radar systems, missile launchers, and electro-optic turrets.

Built under the TEDEG motor control system, the Mil-Drive-55 IP67 motor drive features a MIL-STD-810G / MIL-STD-461F compliant design, offering durability against vibration, shock, humidity, and electromagnetic interference.

This ensures reliable and uninterrupted operation under harsh environmental conditions, including outdoor, marine, and mobile platforms.

Its fanless, passively cooled structure and IP67 protection rating allow safe operation in dusty, wet, and high-vibration environments without the need for active airflow.

Designed as an intelligent motor control unit, the Mil-Drive-55 connects to central command systems via RS-485 and CAN-Bus communication protocols.

This enables operators to remotely monitor and manage motor speed, torque, temperature, and fault conditions.

Additionally, the system’s advanced telemetry and fault reporting algorithms maximize mission reliability during field operations.

In summary, the purpose of the Mil-Drive-55 is to:

- Process platform I/O signals and sensor feedback to intelligently control the motor.

- Manage motor speed, torque, and direction with high precision using FOC motor drive algorithms.

- Enhance operational safety with the Safe Torque Off (STO) function.

- Ensure full integration with central control systems through RS-485 and CAN-Bus communication.

- Deliver uninterrupted performance under harsh conditions with its MIL-STD-810G / MIL-STD-461F compliant and IP67-protected design.

In conclusion, the Mil-Drive-55 Military Motor Drive is not merely designed to drive a motor — it is built to manage energy, control motion, and guarantee mission safety.

Through the TEDEG motor control system, it provides a smart, reliable, and sustainable power management solution for defense and industrial platforms alike.

What It Does

The Mil-Drive-55 Military Motor Drive and Control Unit is an intelligent motor control system designed to precisely control the speed, torque, and direction of three-phase motors used in military platforms, enhance energy efficiency, and ensure maximum mission safety.

Built on the TEDEG motor control system architecture, the product continuously analyzes, processes, and manages platform power inputs, I/O signals, and sensor feedback in real time.

As a result, the Mil-Drive-55 not only drives motors but also acts as a fully integrated motion and power management platform, optimizing overall system performance.

Using Field Oriented Control (FOC) algorithms, the Mil-Drive-55 FOC motor drive calculates the motor’s magnetic field instantaneously to achieve high-precision speed and torque regulation.

This advanced control structure ensures stable operation even during sudden load changes, while reducing mechanical stress on the motor.

Its passively cooled, IP67-rated fanless design allows for silent operation and ensures reliable performance under harsh environmental conditions such as dust, humidity, rain, and vibration.

The integrated Safe Torque Off (STO) safety function immediately cuts motor torque in emergency situations, guaranteeing operator and system safety.

This feature is particularly critical in defense applications such as armored ground vehicles, radar systems, electro-optic turrets, and missile launchers, where uninterrupted performance and fail-safe operation are essential.

Additionally, through RS-485 and CAN-Bus communication protocols, the device maintains bidirectional communication with central control units.

This allows operators to monitor key parameters — such as motor performance, temperature, current, voltage, and fault status — in real time.

Developed within the TEDEG motor control system, the Mil-Drive-55 meets MIL-STD-810G / MIL-STD-461F standards for vibration, shock, humidity, temperature variation, and electromagnetic compatibility, ensuring continuous, fault-free operation in land, naval, radar, and mobile mission platforms.

Its robust design and reliability make it ideal for long-term, high-demand military environments.

In summary, the Mil-Drive-55 serves to:

- Intelligently drive motors by processing platform I/O and sensor feedback in real time.

- Control motor speed, torque, and direction with high precision using the FOC motor drive algorithm.

- Ensure mission safety through the Safe Torque Off (STO) function.

- Maintain constant communication with central systems via RS-485 and CAN-Bus protocols.

- Deliver reliable performance under harsh conditions through its passively cooled, IP67 motor drive design.

- Fully meet military durability requirements with its MIL-STD-810G / MIL-STD-461F compliant structure.

In conclusion, the Mil-Drive-55 Military Motor Drive does far more than operate a motor —

it manages power, controls motion, and ensures operational continuity across the entire platform.

Developed by TEDEG Defense, this intelligent motor control unit represents a new generation of high-precision, safe, and durable motor control solutions for the defense industry.

Where It Is Used

The Mil-Drive-55 Military Motor Drive and Control Unit is an intelligent motor control system designed to provide precise speed and torque control for three-phase motors used in land, naval, and airborne military platforms, as well as industrial mission systems.

With its TEDEG motor control system architecture, the device processes platform I/O signals and sensor feedback (resolver, encoder, NTC, emergency inputs, STO, RS-485, CAN-Bus, etc.) in real time to dynamically manage motor drive operations.

This capability makes the Mil-Drive-55 easily adaptable to various mission types and platform configurations.

Use in Armored Land Vehicles

The Mil-Drive-55 Military Motor Drive is used in armored combat vehicles, tactical wheeled vehicles, turret systems, and command-control platforms.

It controls motorized drive systems, turret rotation mechanisms, directional units, and auxiliary electric drive motors within these vehicles.

Thanks to its FOC motor drive technology, the system ensures stable torque and speed control under varying load conditions.

Its IP67 motor drive structure and MIL-STD-810G / MIL-STD-461F compliant design guarantee continuous operation under vibration, dust, humidity, and electromagnetic stress conditions commonly encountered in armored vehicles.

Use in Radar, Antenna, and Electro-Optical Systems

The Mil-Drive-55 FOC motor drive provides high-precision motion control for radar antenna positioning systems, electro-optic turrets, and stabilized sensor platforms.

With resolver or encoder-based feedback, the system manages the orientation of antennas and sensors with millisecond-level precision.

The integrated Safe Torque Off (STO) function enables secure shutdown in case of malfunction, supporting mission continuity and personnel safety.

These capabilities make the Mil-Drive-55 an ideal military motor drive solution for precision positioning and stabilization systems.

Use in Missile Platforms and Mobile Mission Systems

Thanks to its TEDEG motor control system architecture, the Mil-Drive-55 securely drives high-torque servo motors in both fixed and mobile missile launcher platforms.

Its passively cooled, IP67 motor drive design ensures stable performance even in open-field environments exposed to rain, dust, and temperature fluctuations.

As an intelligent motor control unit, it integrates seamlessly with central mission computers through RS-485 and CAN-Bus communication interfaces.

This infrastructure enables remote monitoring, fault reporting, and mission data sharing, providing superior operational awareness.

Use in Naval Platforms

The marine environment presents extreme challenges due to humidity, salt-laden air, and vibration.

The Mil-Drive-55 Military Motor Drive, with its IP67-sealed enclosure and passively cooled structure, offers long-term, reliable operation in onboard servo motor systems, antenna positioning units, and stabilization mechanisms.

Its MIL-STD-810G / MIL-STD-461F compliance ensures stable performance under electromagnetic interference and environmental stress, making it ideal for naval defense systems.

Use in Industrial and Defense Test Systems

The Mil-Drive-55 FOC motor drive is also suited for laboratory environments, production lines, and test facilities where high-precision motor control is required.

Its intelligent motor control architecture provides engineers with remote control, data monitoring, and fault analysis capabilities.

This makes the product not only ideal for military platforms but also a robust motor drive solution for industrial defense infrastructures.

Summary – Typical Applications of the Mil-Drive-55

- Armored land vehicles (drive, steering, and turret control motors)

- Radar and antenna positioning systems

- Electro-optic turrets and stabilized sensor platforms

- Missile launchers and mobile mission systems

- Naval platforms and onboard actuation systems

- Industrial testing and production infrastructures

In conclusion, the Mil-Drive-55 Military Motor Drive, developed with TEDEG’s intelligent motor control system architecture, integrates military-grade durability, secure power management, and high-precision motion control in a single platform.

With its FOC motor drive technology, Safe Torque Off (STO) safety function, and MIL-STD-810G / MIL-STD-461F compliant, IP67-rated design, the TEDEG motor control system delivers a reliable, long-life, and fully integrated motor control solution for both defense and industrial applications.

Key Features

The Mil-Drive-55 Military Motor Drive and Control Unit is designed by TEDEG Defense as a high-performance, intelligent motor control unit built in accordance with military standards.

The system is optimized to drive three-phase asynchronous motors with high precision, enhance energy efficiency, and maximize mission safety.

Combining FOC motor drive technology, Safe Torque Off (STO) safety architecture, and MIL-STD-810G / MIL-STD-461F compliance, the Mil-Drive-55 represents the perfect integration of performance, durability, and reliability for defense applications.

- Advanced Power and Control Features

The Mil-Drive-55 FOC motor drive operates with 230/400 VAC input voltage, providing a 5.5 kW power output.

The system functions in the 0–500 Hz output frequency range and employs Field Oriented Control (FOC) algorithms to continuously analyze the motor’s magnetic field, achieving precise speed and torque control.

Within the TEDEG motor control system, all platform sensor data and I/O signals (resolver, incremental/absolute encoder, NTC, emergency, STO, RS-485, CAN-Bus) are processed via embedded software algorithms, dynamically adapting motor behavior to mission requirements.

Main Power Specifications:

- Nominal Power: 5.5 kW

- Input Voltage: 230/400 VAC ±10%, 50/60 Hz

- Output Frequency: 0 – 500 Hz

- Output Current: 14 A nominal (up to 175% short-term)

- Energy Efficiency: >90%

- Overload Capacity: 150% (60 sec), 175% (2.5 sec)

- Intelligent Control and Communication Features

The Mil-Drive-55 Military Motor Drive operates with an MCU-based central control board built as an intelligent motor control unit.

This controller manages motor speed, torque, and direction using FOC algorithms, while also enabling Safe Torque Off (STO) functionality and bidirectional communication through RS-485 and CAN-Bus protocols.

Operators can remotely monitor system status and access real-time data on temperature, current, voltage, and fault conditions.

Intelligent Control Features:

- RS-485 / CAN-Bus dual communication support

- Remote ON/OFF control

- Safe Torque Off (STO) dual-channel safety function

- Real-time voltage, current, and temperature monitoring

- Built-in fault detection and protection reporting system

- Automatic Built-In Test (BIT) – two self-check cycles per second

These features make the Mil-Drive-55 FOC motor drive not just a motor driver, but a field-ready, data-driven motor control system for mission-critical applications.

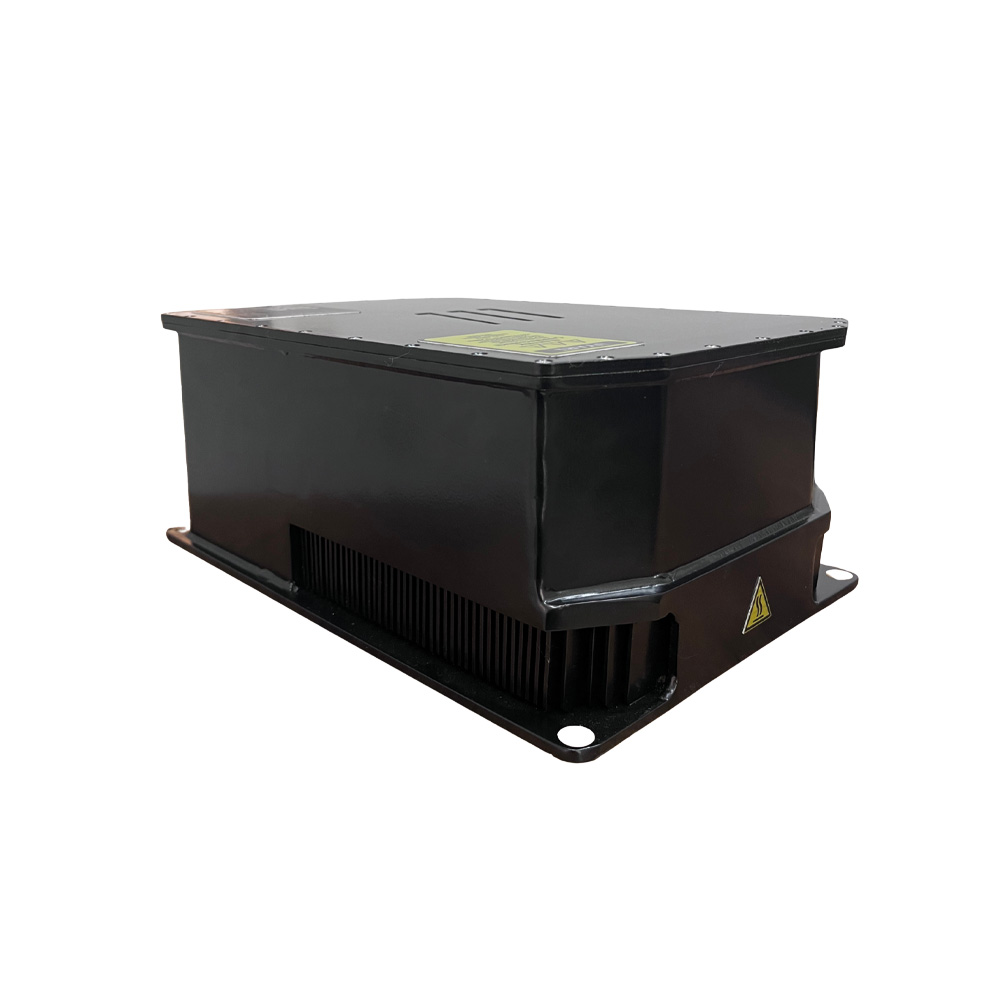

- Durability, Cooling, and Protection Features

The Mil-Drive-55 IP67 motor drive utilizes a passively cooled, fanless design, eliminating moving parts for silent operation, low maintenance, and extended service life.

Its aluminum alloy IP67-sealed enclosure ensures full protection under harsh environments and allows safe operation between -30°C and +55°C.

Compliant with MIL-STD-810G / MIL-STD-461F, the device withstands vibration, shock, humidity, dust, and electromagnetic interference without performance degradation.

Environmental and Protection Features:

- Protection Level: IP67

- Cooling Type: Passive (fanless)

- Operating Temperature: -30°C to +55°C

- Resistance: Vibration, shock, and humidity per MIL-STD-810G

- Electromagnetic Compatibility: MIL-STD-461F

- Silent, maintenance-free operation

- Safety and Protection Functions

The Mil-Drive-55 Military Motor Drive includes advanced protection systems that safeguard the motor, platform, and operator.

Its Safe Torque Off (STO) function immediately cuts motor torque during emergency events, while built-in protection circuits ensure comprehensive system safety.

Protection Functions:

- OVP (Over Voltage Protection) – Prevents voltage spikes

- OCP / OLP (Over Current / Over Load Protection) – Protects against current surges and overload

- OTP (Over Temperature Protection) – Prevents overheating

- Short Circuit Protection – Isolates faults instantly

- Power OK Alarm – Provides power loss or fault indication

This multi-layer protection architecture reflects the mission safety principles standardized across the TEDEG motor control system product line.

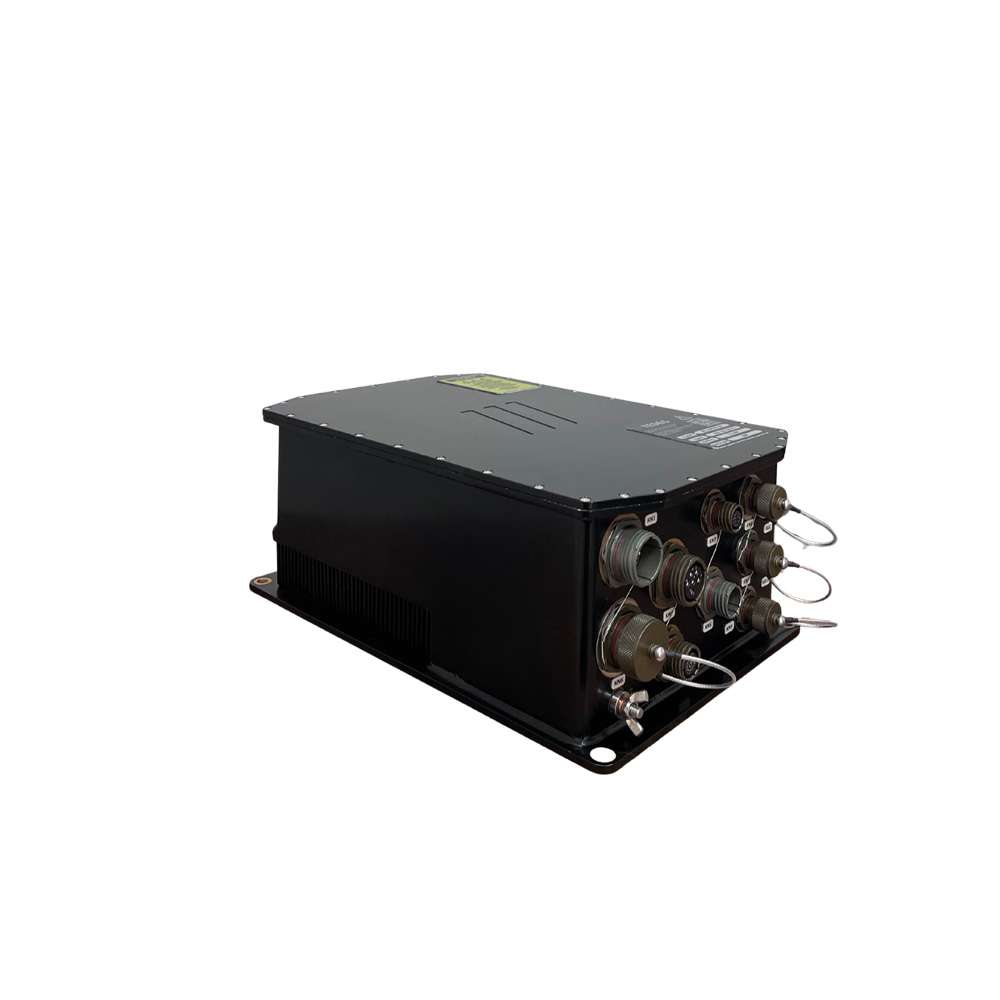

- Mechanical and Connectivity Features

The Mil-Drive-55 integrates seamlessly into harsh environments using MIL-DTL-38999 military-grade connectors.

It is compact, lightweight, and mechanically robust, designed for use in high-vibration defense platforms.

Mechanical Specifications:

- Dimensions: 245 × 350 × 145 mm

- Weight: 12 kg

- Connector Type: MIL-DTL-38999 Series

- Mounting: Vibration-damping base plate

Conclusion

In summary, the Mil-Drive-55 Military Motor Drive — featuring FOC motor drive technology, the Safe Torque Off (STO) safety function, and MIL-STD-810G / MIL-STD-461F compliant IP67 protection — stands as the most advanced product in the TEDEG motor control system family.

This intelligent motor control unit delivers long-term, reliable, and stable performance in demanding environments, uniting power, precision, and durability within a single compact defense-grade system.

How It Works

The Mil-Drive-55 Military Motor Drive and Control Unit operates based on an intelligent motor control architecture developed by TEDEG Defense.

The system processes power, I/O signals, and sensor feedback received from the platform in real time, forming a dynamic control algorithm (FOC – Field Oriented Control) internally.

Through this algorithm, the Mil-Drive-55 continuously optimizes motor speed, torque, and directional parameters according to mission scenarios, providing high-precision and stable motor control under all operating conditions.

- Input Stage – Power and Signal Acquisition

The Mil-Drive-55 FOC motor drive receives 230/400 VAC power input and analog/digital I/O signals from the platform.

These include resolver or encoder feedback, NTC temperature sensors, emergency stop, Safe Torque Off (STO), RS-485, and CAN-Bus communication lines.

The device analyzes these signals through high-speed ADC and DSP processors, determining the motor’s real-time operating status.

At this stage, the TEDEG motor control system filters and isolates all incoming signals, suppressing electromagnetic interference (EMI) to ensure clean data flow.

This design enables stable and safe operation, particularly in MIL-STD-810G / MIL-STD-461F compliant military environments.

- Processing Stage – Embedded Software and Control Loop

At the core of the device lies an MCU-based control board that executes the FOC (Field Oriented Control) algorithm.

This control unit continuously measures current and voltage across the motor windings, resolves the magnetic field vectorially, and manages the speed–torque relationship with extreme precision.

The Mil-Drive-55 Military Motor Drive performs thousands of control operations per second, forming a high-frequency closed-loop system.

In each cycle, the controller:

- Calculates rotor position in real time,

- Adjusts motor current relative to reference torque,

- Applies dynamic corrections based on feedback sensors.

As a result, the motor maintains stable, low-noise, and efficient performance, even under sudden load or directional changes.

This real-time processing chain represents the core of the intelligent motor control unit software, setting the Mil-Drive-55 apart from conventional drives.

- Output Stage – Precision Motor Drive

The processed control signals are transmitted to a three-phase IGBT-based inverter module.

This inverter regulates the voltage and current delivered to the motor windings through PWM (Pulse Width Modulation) control.

The result is precise torque and speed generation with over 90% energy efficiency.

Each motor output is electrically isolated, ensuring EMC compatibility with other onboard electronic systems.

This makes the Mil-Drive-55 FOC motor drive ideal for servo motor applications in radar systems, electro-optic turrets, missile platforms, and armored vehicles, providing clean, stable, and interference-free power transfer.

- Safety and Protection Stage – STO and System Monitoring

The Mil-Drive-55 IP67 motor drive incorporates the Safe Torque Off (STO) safety function to ensure mission safety.

This feature physically disconnects torque generation during emergency events, completely preventing motor rotation.

The STO system is dual-channel and designed to meet ASIL-D level safety requirements.

Additionally, the device integrates multiple protection layers, including:

- OCP (Over Current Protection)

- OVP (Over Voltage Protection)

- OTP (Over Temperature Protection)

- Short Circuit Protection

This comprehensive protection structure upholds the mission continuity and user safety principles that define the TEDEG motor control system product family.

- Cooling and Environmental Operation Stage

The Mil-Drive-55 Military Motor Drive features a completely passive cooling system.

There are no fans or moving parts; heat is dissipated naturally through integrated aluminum cooling fins via convection.

This design ensures reliable operation in harsh environmental conditions such as dust, humidity, rain, and salt-laden air.

The IP67-rated enclosure enables short-term submersion and full compatibility with outdoor mission environments.

Tested for compliance with MIL-STD-810G / MIL-STD-461F, the Mil-Drive-55 delivers consistent performance and electromagnetic compatibility across all environments — from armored land vehicles to naval platforms.

- Communication and Feedback Stage

The Mil-Drive-55 establishes bidirectional communication with central systems via RS-485 and CAN-Bus interfaces.

It continuously transmits real-time data — including motor speed, torque, temperature, current, and fault status — while also receiving operator commands.

This capability is a core part of the intelligent motor control unit design, enabling remote monitoring, maintenance, and diagnostics.

The TEDEG motor control system communication architecture allows the drive to seamlessly integrate with both onboard control units and external mission computers, ensuring full platform interoperability.

Conclusion

The Mil-Drive-55 FOC motor drive is an intelligent, rugged, and safety-focused motor control unit that processes power and sensor data in real time through embedded control algorithms.

With its Safe Torque Off (STO) safety architecture, IP67 protection, and MIL-STD-810G / MIL-STD-461F compliant design, the TEDEG motor control system delivers high accuracy, superior energy efficiency, and continuous mission reliability across modern military platforms.

Components and Architecture

The Mil-Drive-55 Military Motor Drive and Control Unit is a modular drive platform developed through TEDEG motor control system engineering, designed as an intelligent motor control unit for advanced military and industrial applications.

The system is composed of power conversion modules, a central control board, communication interfaces, a Safe Torque Off (STO) safety circuit, a cooling and protection enclosure, and military-grade connection interfaces.

All components are MIL-STD-810G / MIL-STD-461F compliant and fully integrated within an IP67-sealed housing.

- Power Conversion Modules

The Mil-Drive-55 FOC motor drive converts 230/400 VAC input voltage into PWM-based three-phase output signals required to drive asynchronous motors, using an IGBT-based inverter circuit.

This module dynamically regulates voltage, current, and frequency according to the motor’s power demand.

Primary functions of the power modules:

- Isolate 230/400 VAC input and convert it into a stable DC bus voltage.

- Generate three-phase PWM output compatible with the FOC control algorithm.

- Measure feedback currents and relay them into the control loop.

- Provide >90% energy efficiency.

This structure gives the Mil-Drive-55 Military Motor Drive high efficiency, stable power delivery, and field-level durability required for mission-critical environments.

- Central Control Board (MCU-Based Control Board)

The central control board serves as the “brain” of the system — an intelligent motor control unit that manages all operational functions.

Built on an MCU (Microcontroller Unit) processor, it executes the Field Oriented Control (FOC) algorithm for precise control of motor speed, torque, and direction, while also managing safety, communication, and protection mechanisms.

Main functions of the Central Control Board:

- Receive and process motor speed, current, and voltage feedback.

- Analyze resolver/encoder signals.

- Process Safe Torque Off (STO) signals to instantly disable torque.

- Manage RS-485 / CAN-Bus communication.

- Execute Built-In Test (BIT) functions automatically.

- Perform fault detection, data logging, and error reporting.

This control board is the core of the TEDEG motor control system architecture and a defining feature that distinguishes the Mil-Drive-55 from standard industrial drives.

- Communication Interfaces

The Mil-Drive-55 is equipped with RS-485 and CAN-Bus-based communication interfaces.

These interfaces enable secure and uninterrupted data exchange between the drive and central mission computers, radar control systems, or onboard command units.

Communication Features:

- RS-485 (Modbus RTU) and CAN-Bus protocols.

- High-speed data transfer up to 10 Mbps.

- Support for remote configuration, monitoring, and fault reporting.

- Fully bidirectional data communication.

This communication infrastructure allows the Mil-Drive-55 Military Motor Drive to achieve seamless integration with a platform’s digital ecosystem, fully performing its role as an intelligent motor control unit.

- Safety and Protection Circuits

The device includes multi-layer safety circuits, including the Safe Torque Off (STO) function.

The STO circuit instantly cuts motor torque generation when an emergency signal is received from the operator or system.

Additionally, the device features advanced protection functions, such as overcurrent (OCP), overvoltage (OVP), overtemperature (OTP), and short circuit protection.

These protection layers ensure that:

- Both motor and drive safety are maintained.

- The system safeguards itself from operator or system faults.

- Mission continuity remains uninterrupted.

This safety-oriented design reflects TEDEG’s defense-grade engineering philosophy and its commitment to operational reliability under all mission conditions.

- Cooling and Enclosure System

The Mil-Drive-55 IP67 motor drive is housed in a fully passively cooled aluminum enclosure.

The absence of fans or air vents eliminates moving parts, ensuring silent operation, minimal maintenance, and extended service life.

Heat is dissipated naturally through integrated aluminum cooling fins using convection.

Enclosure and Environmental Features:

- Protection Level: IP67 (dustproof, waterproof, and moisture-resistant).

- Operating Temperature Range: -30°C to +55°C.

- Compliance with MIL-STD-810G (vibration, shock, humidity, rain).

- Compliance with MIL-STD-461F (electromagnetic compatibility).

- Silent and maintenance-free operation.

This structure makes the Mil-Drive-55 Military Motor Drive ideally suited for outdoor, marine, and armored vehicle environments.

- Connection Interfaces

The Mil-Drive-55 is equipped with MIL-DTL-38999 series military connectors, ensuring secure, vibration-resistant, and EMI-shielded connections.

These connectors enable quick and reliable integration into field platforms.

Connector Types:

- Input: MIL-DTL-38999 Power Connector (AC Input).

- Output: MIL-DTL-38999 Motor Output Connector (3-phase).

- Communication: RS-485 / CAN-Bus terminal or military-grade connector.

- Sensors: Resolver/Encoder input, NTC temperature sensor connection.

These interfaces ensure secure communication and power delivery between the intelligent motor control unit and the platform.

Summary – Main Components of the Mil-Drive-55

Component | Function |

Power Conversion Modules | Convert AC input into isolated PWM power for motor drive. |

Central Control Board | Manages speed, torque, and direction via FOC algorithm. |

Communication Interfaces | Facilitate data exchange with central systems via RS-485 / CAN-Bus. |

STO & Safety Circuits | Ensure immediate and safe motor shutdown during emergencies. |

Cooling & Enclosure System | Provide IP67-rated, passively cooled housing for reliable operation. |

Military Connectors | Enable robust input/output connections using MIL-DTL-38999 series. |

Conclusion

The Mil-Drive-55 Military Motor Drive, equipped with FOC motor drive technology, Safe Torque Off (STO) architecture, an IP67-sealed enclosure, and MIL-STD-810G / MIL-STD-461F compliant design, represents the most advanced intelligent motor control unit within the TEDEG motor control system family.

With all its components working together, it delivers an integrated, high-performance, and mission-ready motor drive platform designed for demanding defense applications that require reliability, precision, and robust power management.

Test Standards and Compliance

The Mil-Drive-55 Military Motor Drive and Control Unit is a high-durability intelligent motor control system developed under the TEDEG motor control system engineering framework and fully compliant with international military standards.

The product meets all the requirements of MIL-STD-810G and MIL-STD-461F, proving its ability to operate safely in electromagnetically complex and environmentally demanding military platforms.

Additionally, the unit is IP67-rated and has passed TEDEG’s advanced in-house quality and safety tests.

These certifications demonstrate that the Mil-Drive-55 Military Motor Drive is not only a control unit but a mission-safety-oriented military hardware solution.

- MIL-STD-810G – Environmental Durability Tests

MIL-STD-810G defines environmental test standards set by the U.S. Department of Defense to evaluate product durability in extreme conditions.

The Mil-Drive-55 FOC motor drive has successfully passed all relevant environmental tests.

Tests and Results:

Test Type | Description & Result |

Vibration | Maintains full mechanical stability under continuous vibration. Suitable for armored, naval, and mobile platforms. |

Shock | Withstands impacts and sudden shocks without deformation or performance loss. |

Humidity | Operates flawlessly under 95% relative humidity with no condensation or corrosion. |

Rain Exposure | IP67-sealed enclosure provides total protection against rain, hail, and water spray. |

Thermal Cycle | Performs reliably between -30°C and +55°C with continuous thermal stability. |

Sand & Dust | Passive cooling design prevents contamination by external particles — fanless and sealed. |

These tests confirm that the Mil-Drive-55 Military Motor Drive can operate reliably across land, sea, and air platforms in long-duration missions.

- MIL-STD-461F – Electromagnetic Compatibility (EMI/EMC) Tests

MIL-STD-461F defines the levels of electromagnetic interference (EMI) and electromagnetic compatibility (EMC) acceptable for military equipment.

The Mil-Drive-55 IP67 motor drive is designed to minimize EMI emissions and maintain stable operation in high-interference environments.

Test Results:

- Radiated Emissions: Low noise level (max. 150 mVp-p ripple) prevents interference with nearby electronics.

- Conducted Emissions: Power line noise fully filtered; system operates stably alongside other electronic units.

- Radiated Susceptibility: Maintains full functionality under strong RF signals or electromagnetic pulses.

- Grounding & Shielding: Fully isolated modules eliminate feedback loops and minimize electromagnetic noise.

These tests validate the TEDEG motor control system’s military-grade EMC performance, confirming the Mil-Drive-55 FOC motor drive as a reliable choice for radar, communications, and C4ISR platforms.

- IP67 Protection Rating – Dust and Water Resistance

The Mil-Drive-55 Military Motor Drive is built to the IP67 protection standard, making it completely dustproof and water-resistant.

It can operate submerged up to 1 meter for 30 minutes while maintaining full functionality.

Key IP67 Benefits:

- Complete insulation against dust, mud, and water ingress.

- Fanless passive cooling eliminates airflow and particle intrusion.

- Fully suitable for naval, land, and mobile mission systems.

These characteristics reinforce the environmental durability of the TEDEG motor control system, making the Mil-Drive-55 a trusted solution for defense operations in any terrain.

- TEDEG Quality and Safety Tests

In addition to international certifications, the Mil-Drive-55 FOC motor drive undergoes rigorous in-house validation under TEDEG Defense’s Quality Assurance Program.

Each unit is individually tested during production under real operating conditions.

TEDEG Test Protocols:

- Functional Test: Verification of all I/O and communication ports.

- Short Circuit Test: Measurement of protective circuit response times.

- Thermal Endurance Test: Five-hour full-load operation to confirm thermal stability.

- BIT (Built-In Test): Continuous self-diagnostic loops to ensure system health.

This process aligns with TEDEG’s “zero fault tolerance” policy, ensuring each Mil-Drive-55 Military Motor Drive delivers long-term reliability and mission readiness.

- Summary – Compliance Standards

Standard / Test | Description |

MIL-STD-810G | Environmental durability (vibration, shock, humidity, temperature, dust) – passed all tests. |

MIL-STD-461F | Full compliance with EMI/EMC electromagnetic compatibility tests. |

IP67 | Complete dust and water protection for outdoor and marine operation. |

TEDEG QA Tests | Functional, thermal, and safety verification applied during production. |

Operating Range | -30°C to +55°C, passively cooled, silent, and reliable. |

Conclusion

The Mil-Drive-55 Military Motor Drive, compliant with MIL-STD-810G / MIL-STD-461F, featuring IP67 protection and Safe Torque Off (STO) functionality, fully meets modern military platform requirements.

Through its verified engineering quality, the TEDEG motor control system establishes itself as one of Turkey’s most reliable indigenous intelligent motor control solutions.

This high level of resilience makes the Mil-Drive-55 FOC motor drive ideal for long-term missions in defense, naval, and industrial environments, ensuring continuous operation, durability, and mission safety.

Additional information

| Nominal Power | 5.5 kW |

|---|---|

| Output Voltage | 3 × 400 VAC |

| Output Frequency | 0 – 500 Hz |

| Motor Current | 14 A |

| Input Voltage | 400 VAC ±10% |

| Input Frequency | 48 – 62 Hz |

| Phase Imbalance | Max. 3% |

| Control Modes | Sensored / Sensorless FOC |

| PID Control | Built-in PI Algorithm |

| Start/Stop Function | Ramp-up / Ramp-down, 0.1 – |

| PWM Frequency | 4 – 32 kHz (Selectable) |

| Safety Functions | STO (Dual Channel), Emergency |

| Protocols | RS-485 (Modbus RTU), CANBus |

| Baud Rate | 9600 – 115200 bps |

| Output Data | Operating status, fault codes, |

| Resolver | SIN, COS, REF inputs |

| Incremental Encoder | A, B, I channels |

| Absolute Encoder | DATA±, CLOCK± |

| Thermistor Input | NTC/PTC motor winding |

| Dimensions | 245 × 350 × 145 mm |

| Weight | 12 ± 0.5 kg |

| Enclosure Material | Aluminum 6000 series |

| Connectors | MIL-DTL-38999 series |

| Operating Temperature | –30°C … +55°C |

| Humidity Resistance | 95% RH |

| Durability Standards | MIL-STD-810G (vibration, shock, |

| Operating Hour Meter | Built-in |

| Status Indicators | LED |

| Optional Display | OLED screen support |

TECHNICAL DOCUMENT - EN

Mil-Drive-55 Military Motor Drive and Control Unit

Additional information

| Nominal Power | 5.5 kW |

|---|---|

| Output Voltage | 3 × 400 VAC |

| Output Frequency | 0 – 500 Hz |

| Motor Current | 14 A |

| Input Voltage | 400 VAC ±10% |

| Input Frequency | 48 – 62 Hz |

| Phase Imbalance | Max. 3% |

| Control Modes | Sensored / Sensorless FOC |

| PID Control | Built-in PI Algorithm |

| Start/Stop Function | Ramp-up / Ramp-down, 0.1 – |

| PWM Frequency | 4 – 32 kHz (Selectable) |

| Safety Functions | STO (Dual Channel), Emergency |

| Protocols | RS-485 (Modbus RTU), CANBus |

| Baud Rate | 9600 – 115200 bps |

| Output Data | Operating status, fault codes, |

| Resolver | SIN, COS, REF inputs |

| Incremental Encoder | A, B, I channels |

| Absolute Encoder | DATA±, CLOCK± |

| Thermistor Input | NTC/PTC motor winding |

| Dimensions | 245 × 350 × 145 mm |

| Weight | 12 ± 0.5 kg |

| Enclosure Material | Aluminum 6000 series |

| Connectors | MIL-DTL-38999 series |

| Operating Temperature | –30°C … +55°C |

| Humidity Resistance | 95% RH |

| Durability Standards | MIL-STD-810G (vibration, shock, |

| Operating Hour Meter | Built-in |

| Status Indicators | LED |

| Optional Display | OLED screen support |